Electrical circuit breakers serve as the first line of defense in protecting your home from a possible incident. Typical electrical breakers will do their job without a problem for years or even decades. When they stop working properly, it can lead to many functional issues and several potential safety risks. Here is a look at how electrical breakers may fail and what the associated signs of failure tend to be from the electrical team at Air Control Home Services.

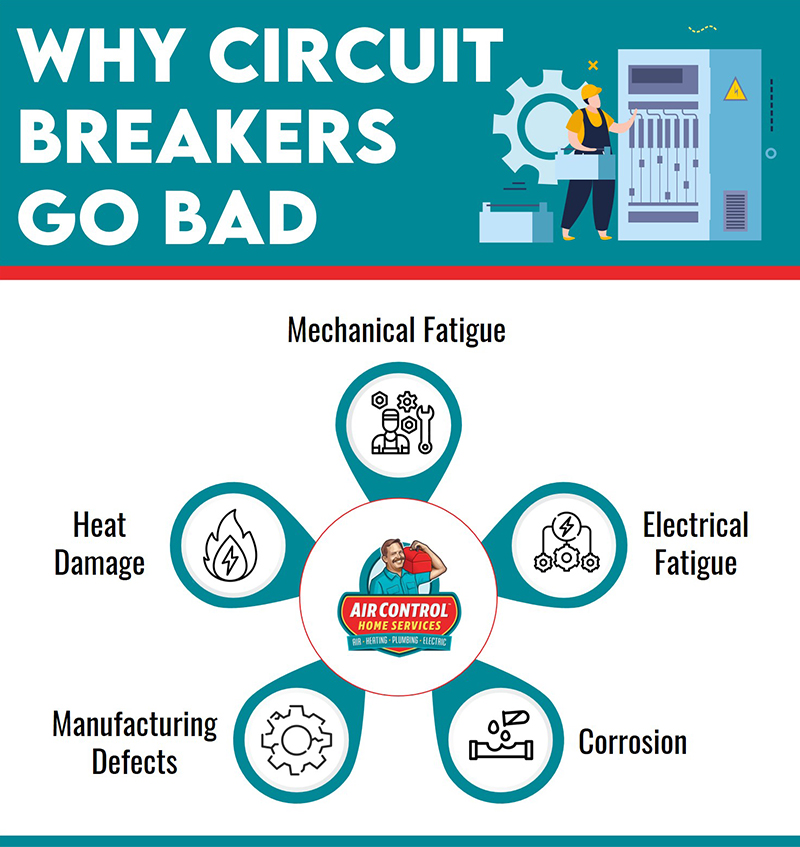

Mechanical Fatigue

A breaker is effectively a switch, and it operates mechanically, just like any other on-off switch. The components tend to be stiffer, though. Consequently, the influence of mechanical fatigue makes weakening more obvious than it might be with a normal switch. Friction can also wear the metal down. Likewise, banging or even constant vibrations can loosen soldered components.

Wear and tear causes the metal components inside the breaker to lose their springiness. Over time, this can cause the metal to move farther from closing the circuit. More worrisome, the electricity will still try to jump the gap for a while. Consequently, the circuit breaker may operate in an unsafe condition because the electricity is arcing.

There are several signs of mechanical fatigue in a circuit breaker. First, it might not trip as quickly as it should. Second, it could trip intermittently or only when under extremely high loads. Third, there may be an electrical sound near the box because of the electricity arcing. Fourth, the breaker could trip faster and more often than it should. Finally, extreme wear could cause the circuit to break permanently to the point where you wouldn’t be able to reset it manually.

Electrical Fatigue

Depending on the nature of the electrical fatigue, the breaker might fail to break or simply trip and then quit working. Electrical fatigue also can cause the breaker to perform poorly, potentially tripping at lower or higher loads than expected.

High-usage circuits are more likely to have breakers that experience electrical fatigue. If someone runs devices that aren’t right for the power specifications on the circuit, this will speed up the process. For example, a high-capacity freezer operating out of spec for the circuit will drive fatigue.

Corrosion

Electrical circuit breakers sit inside panels that are often in locations like basements and service closets. This keeps them out of the way, but they also sit in places where the air usually doesn’t circulate well. Humidity can cause moisture to collect inside the circuit breakers. Over time, the moisture will react with the breakers’ metallic elements.

Notably, the presence of electricity doesn’t help. Electricity often encourages oxidation because it speeds up reactions between chemicals in the humid air and the metals in the breakers. Also, corrosion can cause the breakers to arc, leading to a feedback loop where more reactivity drives more corrosion.

Corroded breakers cause numerous problems. If you use equipment that’s sensitive to signal stability in the line, those devices may not work as well. For example, it could take longer than usual to charge your phone because it’s not getting stable electrical current.

As conductivity breaks down in the circuit, it may trip because of a false positive. Essentially, the breaker detects that something is wrong with the current and flips. This is just because the corrosion is messing with the circuit, but the breaker isn’t advanced enough to handle that scenario.

In extreme cases, you may see visible signs of corrosion. Dirty or rusty materials may collect in the circuit, inside the panel, or below the box.

Unsurprisingly, anything that drives humidity makes corrosion worse. Flooding is always bad, even if you can dry the area out quickly. You should always ask one of our electricians to check the breakers after any flooding has occurred.

Manufacturing Defects

Not every circuit breaker that comes off the factory line is in good enough condition to do the job. Quality control in the industry is excellent, but the process isn’t perfect. Companies sometimes mislabel breakers, leading to installations with the wrong capacities or fittings. Also, internal elements like solder points can suffer damage during the shipping or installation process.

The worst sign of a manufacturing defect in an electrical circuit breaker is a noticeable smell. It may be a detectable smell of ozone if there’s arcing. However, extremely defective breakers that don’t trip can overload. The result is melting plastic in the breaker’s housing, and you can smell smoke as the plastic melts. In the worst-case scenario, the plastic could catch fire.

Another sign of a manufacturing defect is that the breaker fails under normal load far sooner than you’d expect based on the manufacturer’s indications. Alternatively, the breaker might not trip at all, especially if it’s a mislabeled high-capacity breaker. The breaker also might not fit tightly in the socket if some components are loose. In extreme cases, there could be a noticeable gap around the breaker in the socket.

Heat Damage

Over the lifetime of any electrical circuit breaker, a lot of heat will transfer through its components. This is normal, but it also will affect the breaker’s performance with age. Particularly, thermal trip elements inside the breaker will slowly stop performing at their expected breaking points. Especially if a circuit breaker has exceeded its mechanical life expectancy, you may notice this problem. You can test for it from a distance by pointing a thermal imager at the panel. If you see a warm spot around one breaker or a cluster of breakers, then there’s a good chance that heat is causing some problems.

Heat damage generally causes electrical resistance to increase in a circuit breaker. Higher resistance can trip the thermal element faster. However, a total failure of the breaker might result in it not detecting an overload at all, just allowing the current to flow through no matter what.

You may also notice voltage drops that can affect the performance of your household devices. The issue is most common in power tools, but some sensitive electronics may refuse to work if the voltage is too far out of spec.

Note that not all heat damage is age-related. If there is a manufacturing defect, there might be excess heat coming from a circuit breaker early in its anticipated lifespan.

Call Air Control Home Services

Our team at Air Control Home Services performs a host of electrical services for residents of Lake Havasu City, AZ and the surrounding area, including work on electrical panels, wiring, lighting, EV chargers, and whole-house surge protection.

If you’re concerned about the electrical breakers in your home, call us right away at Air Control Home Services, so we can send an electrician to find out what’s happening.